One Platform. The Complete Preclinical Journey.

Build your process at 250 mL. Scale to large batch volumes. Same platform, same validated data — no equipment changeover, no re-optimization.

Have Questions First? Schedule a call >

Elastic Scale: One Seamless System

Cell culture scale-up shouldn't require a $400K system, a specialized facility, or months of setup. Evoworks is built around a single-use consumable vessel and configurable hardware that work together, taking you from optimization to large-batch production without switching platforms.

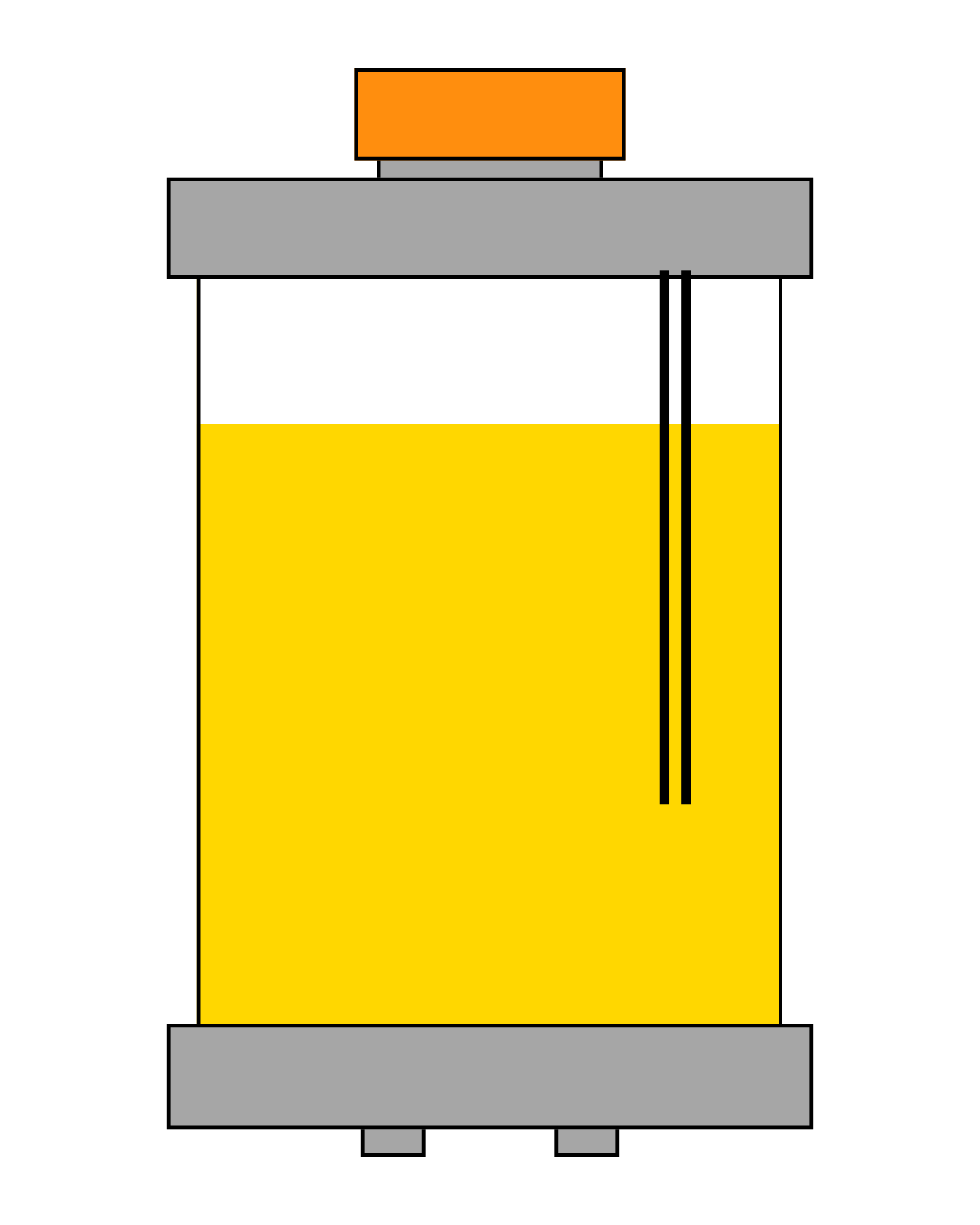

EvoNode —Your Single-Use Vessel

Think of EvoNode as a sophisticated replacement for a shake flask. It's where your cells grow. Single-use design eliminates cleaning validation and cross-contamination risk entirely.

Specifications:

Working volume: 250–550 mL

Sample and feed tubes for aseptic sampling

Semi-permeable membrane for gas exchange

Optional sensor ports for pH, DO, DCO2

Right-sized for efficiency—550 mL in a 550 mL vessel, not a 2 L flask (4X space savings)

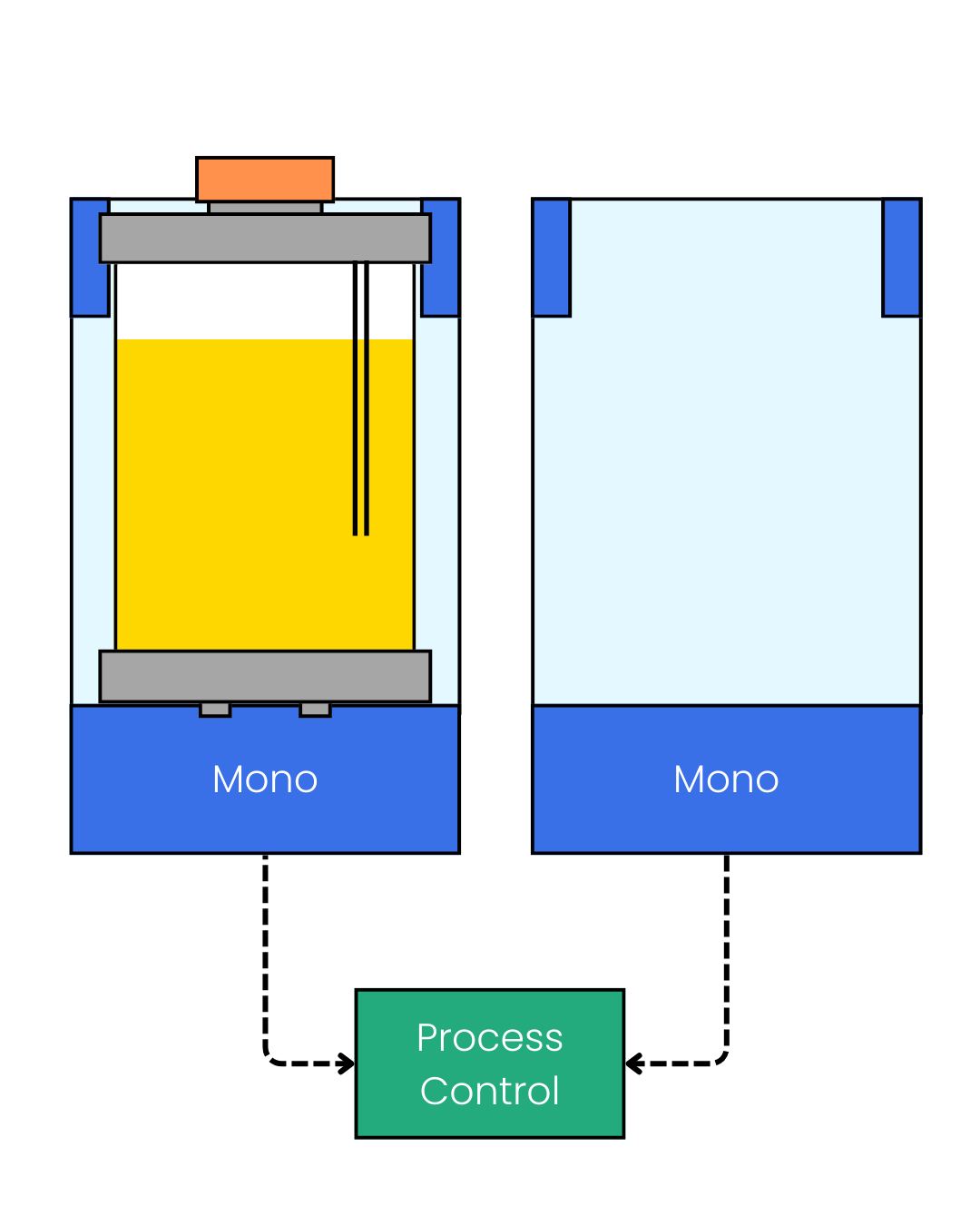

EvoNode Mono — Experiment & Develop

Run up to 12 EvoNodes independently, side by side. Each vessel operates on its own conditions. Best for screening variables, testing protocols, and comparing results in parallel.

Capabilities:

Parallel experiments across multiple conditions

Optional real-time sensing per vessel

Fits into manual workflow—works with your current processes

Optional controls for automated monitoring

Operational in 1 week

Ideal for: Process development, condition screening, early-stage optimization

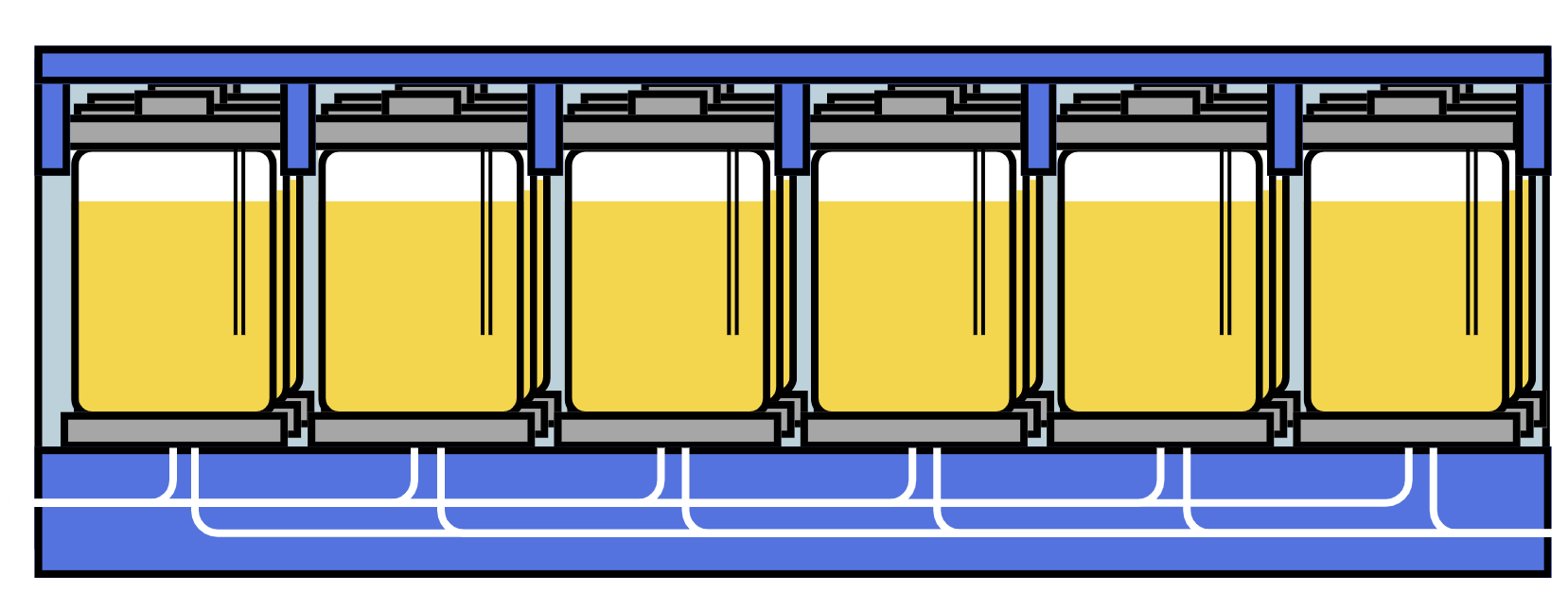

EvoNode Array — Elastic, On-demand Scale-Up

Connect up to 18 EvoNodes into a single integrated array. One system feeds all vessels. Identical conditions across every node. This is how you move from optimization to production volumes without re-validation.

Capabilities:

Replicate ideal conditions across 18 vessels (10 L total volume)

Connect multiple arrays to seamlessly scale-up to 30 L or more

Automated fill and drain

Semi-automated feed delivery

Individual sampling per EvoNode

Modular design fits any large-format shaking incubator

Operational in 2–4 weeks

Ideal for: Producing large batches for animal studies & preclinical material

Key Capabilities for Preclinical Scale-Up

-

Elastic Scalability

Start with a single EvoNode. Add more as your project demands it. Scale from 250 mL to large batches of 10 L+ without switching platforms, process transfers, or re-validation. Move from experiment to production instantly—choose Mono for parallel development or Array for scale-up.

Why teams care: Accelerate timelines by months while lowering costs and eliminating scale-up risk. -

Fits Your Existing Lab

The EvoNode platform is engineered around the infrastructure you already have. Benchtop footprint: 50–165 cm wide × 45 cm deep × 60–65 cm tall (configuration dependent). Fits inside standard incubators and biosafety cabinets. No clean rooms. No additional facilities.

Why teams care: The biggest barrier to new equipment is usually the lab itself. This removes that barrier entirely.

-

Real-Time Monitoring & Data

Optional sensors monitor pH, dissolved oxygen (DO), and dissolved CO2 (DCO2) in real time via optical probes. Data logged automatically throughout every run. pH accuracy to ±0.02 units. DO accuracy to ±2%. The kind of validated data that regulators trust.

Why teams care: You need process data that holds up. The EvoNode platform delivers it without the complexity of over-engineered systems.

-

Rapid Launch for Workflows

Launch biologics capabilities in 1–2 weeks. No specialized facilities. No extensive training—if your team can run shake flasks, they can run Evoworks. Add process development services, expand protein production, or take on new contract types without the 6-month ramp traditional systems require.Why teams care: Respond to market opportunities quickly. Add revenue streams without massive infrastructure investment or specialized hiring.

How the EvoNode Platform Works: Seven Steps to Scale-Up Production

Traditional multi-parallel bioreactor systems require specialized facilities, months of installation, and weeks of operator training. The EvoNode Platform integrates into your existing cell culture workflow in days. Here is what a typical run looks like—from loading to harvest.

Place the EvoNode Array into your existing shaking incubator. The modular design fits standard large-format incubators. Everything works with your current lab setup—no modifications required.

Step 1: Load the Array Into Your Incubator

Connect EvoNode consumables together using aseptic connectors. Consumables maintain the sterile barrier even outside the incubator. All connections can be made in your standard biosafety cabinet.

Step 2: Load and Connect Consumables

Step 3: Prepare Cells and Media

Mix your cell culture media and additives, then add the inoculum. The EvoNode Array system distributes it automatically to all connected vessels—ensuring consistent starting conditions across every node.

Step 4: Automated Fill

Connect your cells and media through the automated pump system. Every EvoNode fills automatically to the same volume using onboard sensors. No manual pipetting required—reducing contamination risk and operator time.

Optional sensors for pH, dissolved oxygen (DO), and dissolved CO2 (DCO2) log data automatically throughout the run. Temperature maintained at 18–55 °C (±0.5 °C). No manual intervention required. Sample per-EvoNode for offline analysis using aseptic sampling ports.

Step 5: Incubate with Real-Time Monitoring

When required, pause the incubator and connect your feed media using the aseptic feed line. Open each valve to feed each EvoNode individually—providing precise fed-batch or perfusion control without breaking sterility.

Step 6: Semi-Automated Feed

Step 7: Harvest Directly

Collect your cell culture product into standard collection vessels. Dispose of single-use EvoNodes. No cleaning validation required. No cross-contamination risk between runs.

Get a quick look at the platform in action >

Built for Teams Stuck Between Shake Flasks and Systems They Can't Afford

-

Early-Stage CDMOs

Win biologics contracts without the capital gamble. The EvoNode Platform delivers validated data at a fraction of the cost—deployed in weeks using your current lab. Scale capacity as contracts close and deliver on aggressive timelines.

-

CROs Expanding Services

Expand from cell line development to protein production without capital constraints. Offer validated preclinical services from day one. Compete for IND-ready contracts previously limited to established players.

-

Small Molecule CDMOs

Add high-margin biologics revenue without massive infrastructure investment. Leverage existing client relationships while entering the fastest-growing segment of contract services.

FAQs

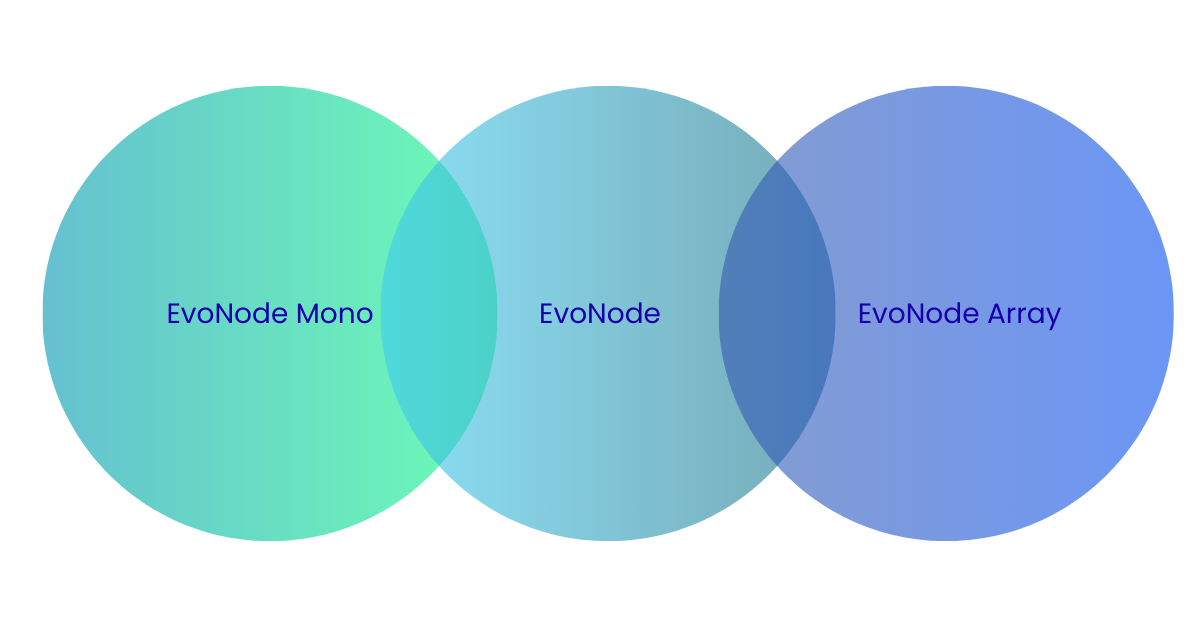

What's the difference between EvoNode, EvoNode Mono, and EvoNode Array?

1

EvoNode is the single-use vessel — think of it as a sophisticated shake flask replacement with sample and feed tubes, semi-permeable membrane, and optional sensor ports. EvoNode Mono is a configuration where you run up to 12 EvoNodes independently for parallel experiments. EvoNode Array connects up to 12 EvoNodes into one system for scale-up (10 L total volume), with automated fill/drain and replicated conditions across all vessels.

Can I start small and scale up later?

2

Yes — that's how the platform is designed. Start with EvoNode Mono for parallel process development. When you need large batch volumes, move to EvoNode Array—same consumable, same validated process. When you need preclinical production scale, step up to LabRack (up to 100 L). No equipment changeover. No re-optimization.

What lab infrastructure do I need?

3

Standard BSL-2 lab infrastructure. The EvoNode Platform fits inside the incubators and biosafety cabinets most teams already have. The Array is modular to fit any large-format shaking incubator. No clean rooms, no facility renovations, no specialized power or ventilation requirements.

How long does setup and training take?

4

EvoNode Mono is operational within 1 week. EvoNode Array takes 2–4 weeks for full setup. Training takes less than 3 days either way. Compare that to 4–8 months for traditional over-engineered systems.

Sensors are optional. Many teams run without them initially and add sensing later as needed. If you need validated process data for regulatory submissions or sponsor deliverables, the optional pH, DO, and DCO2 sensors provide real-time monitoring with automated logging.

5

Do I need the sensors?

It depends on the configuration and scale you need. We'd rather have that conversation directly so we can match the right setup to your situation. Contact our team and we'll walk you through what makes sense.

6

How much does it cost?

Can multiple teams or companies share one system?

7

Yes. For incubator labs and shared facilities, each run uses fresh single-use EvoNodes — zero cross-contamination between users. Shared scheduling across the system. 4X better space efficiency than shake flasks means multiple residents run simultaneously.

What kind of process data does it generate?

8

Optional real-time monitoring of pH (±0.02 accuracy), dissolved oxygen, and dissolved CO2, logged automatically throughout every run via optical probes. Individual sampling per EvoNode for offline analysis. Data is exportable in standard formats.

Does it work for sensitive cell lines?

9

Yes. The EvoNode Platform does not introduce shear stress during culture — a common problem with stirred-tank bioreactors. The semi-permeable membrane provides gentle gas exchange. This makes it well suited for biologics applications where cell viability is critical.

What does a pilot actually look like?

10

A pilot is a hands-on evaluation where you run the EvoNode Platform with your own cells and your own process, in your own lab. Our team supports setup, training, and troubleshooting throughout. It's the fastest way to see whether the EvoNode Platform fits your workflow before making any commitment.